INNOVATIVE SPACE CARRIER INC.(Chuo-ku, Tokyo; CEO; Kojiro Hatada, hereafter referred to as “ISC”) is “a world where people and cargo are delivered every day. We are a start-up company that aims to realize a transportation system that makes space possible, with the vision of “making such things possible in space.

(Head Office: Chuo-ku, Tokyo; CEO: Takuya Yokoyama; hereinafter referred to as “SUPWAT”), a DX platform “WALL” that optimizes the engineering chain* in the manufacturing industry, for the purpose of reducing the weight and increasing the strength of rocket fuel tanks. (headquartered in Chuo-ku, Tokyo; Takuya Yokoyama, CEOCEO; hereinafter referred to as “SUPWAT”) to develop a rocket fuel tank design optimization system and a new structure of fuel tank.

The tank is an important component of a rocket, especially for liquid-fuel rockets, where the fuel and tank account for the majority of the rocket’s overall weight, and therefore, in addition to safety, the tank must be lightweight, efficient in storage, pressure-resistant, and strong. Liquid fuels used in rockets are liquid hydrogen (-253°C), liquid oxygen (-183°C), and liquid methane (-160°C), and these fuels must be able to withstand the harsh cryogenic environment. However, because of the complex behavior of materials used in tanks under cryogenic conditions, it is difficult to predict the behavior of tanks using conventional tank development methods. In addition, when attempting to reduce the weight of tanks, there is a trade-off between weight reduction and strength/rigidity, and safety is often compromised in the development process.

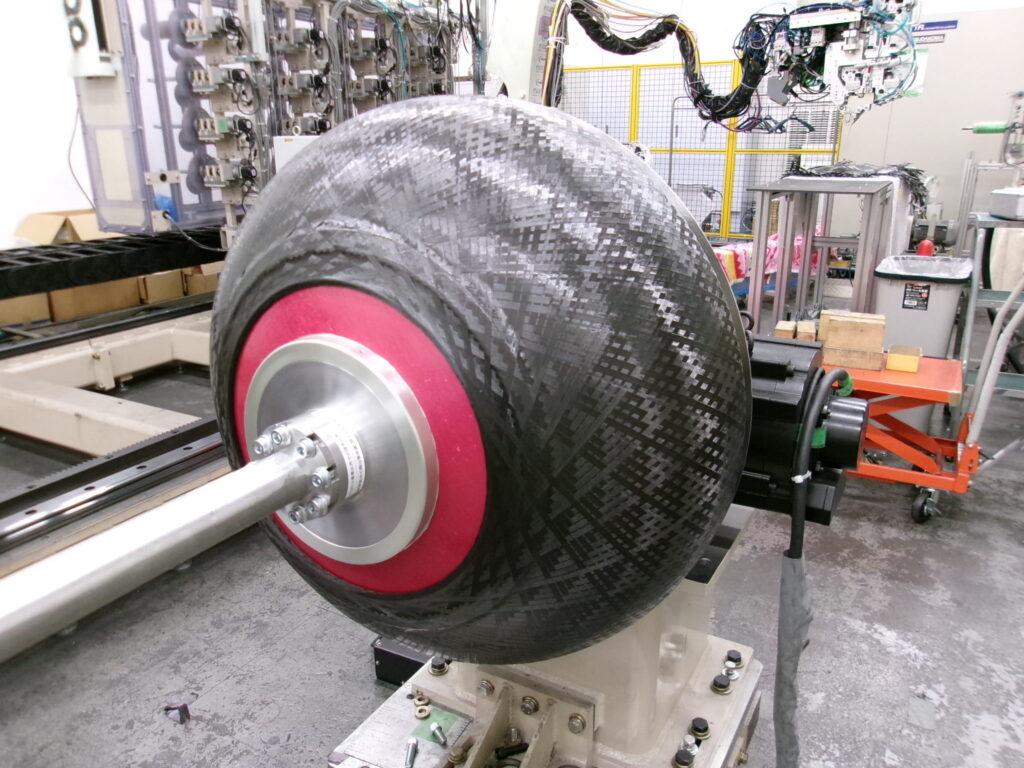

Therefore, with the aim of reducing space transportation costs, the two companies collaborated to develop a cryogenic fuel tank for next-generation rockets with a new structure using carbon fiber reinforced plastic (CFRP) as the main material for the fuel tank, which will reduce the weight and weight of the fuel tank, increase its strength, and lower its cost. The two companies have started development of a design optimization system utilizing the surrogate model under the collaboration of the two companies.

In the first phase of this collaboration, we are working on the development of an AI model to predict mechanical response, etc. (peeling, breaking, etc.) in tank design and a design optimization system using this model, which was completed in December 2024. This model is a surrogate model that combines AI technology and structural analysis, and is an AI model that predicts the mechanical response of a design in a cryogenic environment. By using a design optimization system equipped with this model, multiple design requirements (e.g., weight reduction and safety) can be optimized simultaneously, and we have established this as a practical design method that is compatible with the latest automated laminate fabrication (AFP) technology for tank inner walls.

In the second phase, the design optimization system developed in the first phase is being used to study the optimization of the tank structure, particularly structural analysis to prevent leaks from the tank mouth. Based on the analysis results of the second phase, both companies are working together to develop a fuel tank with a new structure that is both lightweight and safe by expanding the technology for practical use in rockets.

Kojiro Hatada, CEO President, Innovative Space Carrier Inc. comments

While we were looking for a partner to optimize the structural design of rocket tanks, we were surprised to find that we could work with SUPWAT, which is located in the same co-working facility. We believe that the use of AI is one of the most important themes in promoting agile rocket development. We are excited to be able to promote speedy development among startups!

SUPWAT CEO Corporation: Mr. Takuya Yokoyama comments

We are very pleased that our technology is being utilized in the extremely difficult and demanding area of rocket manufacturing.

I feel it is very significant that this collaboration, which began with a chance encounter between two companies that happen to be based in the same place, has come to fruition in this way.

In addition to contributing to the future of space transportation, we will continue to take on the challenge of realizing our vision of “the age of intelligent manufacturing.

■Company Profile

Innovative Space Carrier Inc.

English name : Innovative Space Carrier Inc.

Location : 5F Nihonbashi 1-chome Mitsui Building, 1-4-1 Nihonbashi, Chuo-ku, Tokyo

Representative : Kojiro Hatada, CEO & President

Date of establishment : May 2022

Total funding : 1.22 billion yen

Business overview : Planning and study for the commercialization of innovative space transportation systems

URL :https://innovative-space-carrier.co.jp/

SUPWAT, Inc.

SUPWAT is a manufacturing tech venture that develops and provides the DX platform “WALL” to optimize the engineering chain in the manufacturing industry with the vision of “creating the era of intelligent manufacturing”. SUPWAT has been developing and offering a DX platform called “WALL” to optimize the engineering chain in the manufacturing industry since its inception in 2019, Since its founding in 2019, SUPWAT has been developing WALL, which streamlines, accelerates, and formalizes the cycle of experimentation and analysis in engineering operations, in order to solve problems in the engineering chain of the manufacturing industry with AI and other technologies. WALL has already been adopted by a wide variety of manufacturing enterprises, including automobile and automotive parts manufacturers, materials and chemical manufacturers with sales of tens of billions of yen, and has proven to reduce experimentation and analysis time in the R&D process by over 60%.

Location : 5F Nihonbashi 1-chome Mitsui Building, 1-4-1 Nihonbashi, Chuo-ku, Tokyo

Established : December 2019

Capital : 66,000,000 yen (as of the end of February 2024)

Representative : Takuya Yokoyama, CEO

Business : DX to optimize the engineering chain in manufacturing industry Development of “WALL” platform

URL : SUPWAT Corporation https://www.supwat.com/

WALL https://cs.supwat.com/

*: Engineering Chain: Refers to a series of manufacturing processes in the manufacturing industry centered on the design department. It is a series of business processes centered on design, starting from planning and receiving orders, through design, manufacturing preparation, manufacturing, maintenance and preservation, etc.

■We are actively recruiting human resources!

We want to go to space from Japan.

We take on the challenge.

Aerospace technology x Knowledge of different industries x Backcast thinking

Create new industries with an eye on the future.

Let’s do work that is worth the challenge of our lives.

Click here for the employment page:

https://www.wantedly.com/companies/company_9146989

For business partnerships and other inquiries, click here

https://innovative-space-carrier.co.jp/contact/

■We are accepting “advanced applications” for space travel

Please follow this link to register.

https://forms.gle/TDc8HpdcR2zCU41t9