1. WHAT IS P4SD, THE RESEARCH AND DEVELOPMENT PLATFORM THAT CUTS THE DEVELOPMENT TIME OF NEW ROCKETS IN HALF?

- P4SD (Platform for Space Development), a unique research and development platform for future space transportation systems, is also active in Japan's first "tripropellant" combustion test using three types of propellants (hydrogen, methane, and oxygen) What kind of power does it have? Could you tell us from a development standpoint what kind of capabilities you are demonstrating?

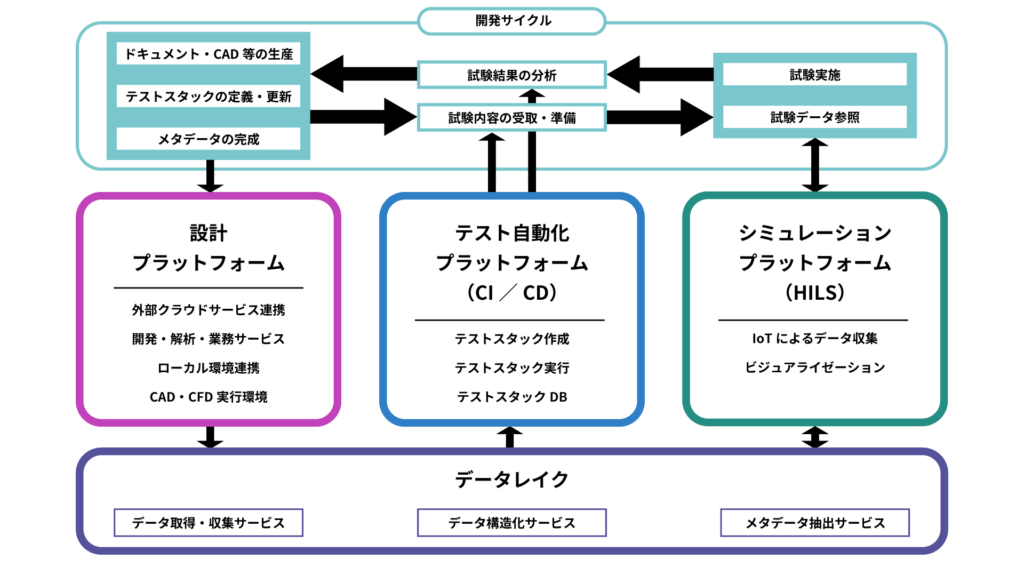

BROADLY SPEAKING, P4SD IS A THREE-PILLAR CONCEPT. THE FIRST IS THE "DESIGN PLATFORM," THE SECOND IS THE "TEST AUTOMATION PLATFORM (CI/CD)," AND THE THIRD IS THE "SIMULATION PLATFORM (HILS). THE THIRD IS THE "SIMULATION PLATFORM (HILS).

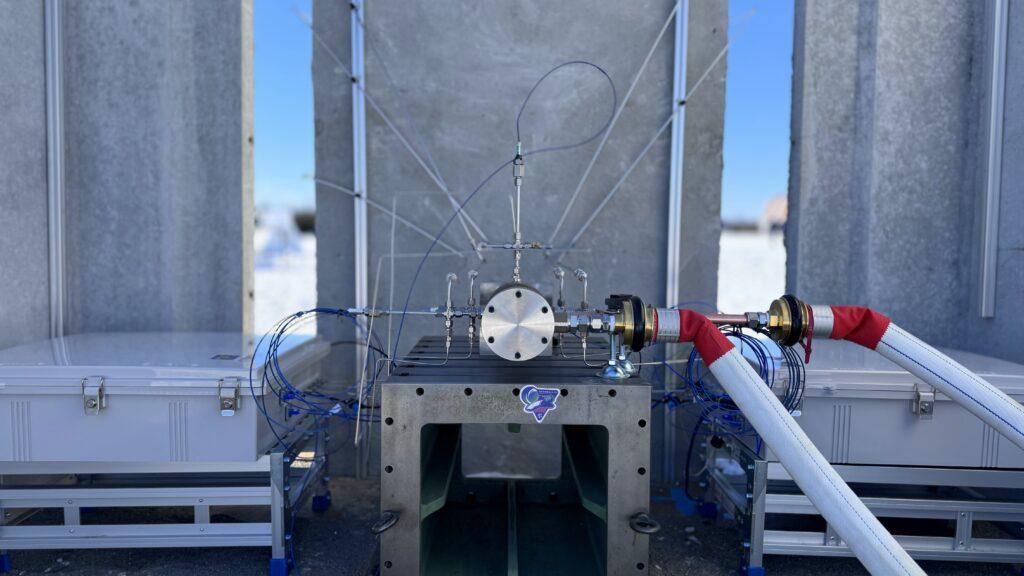

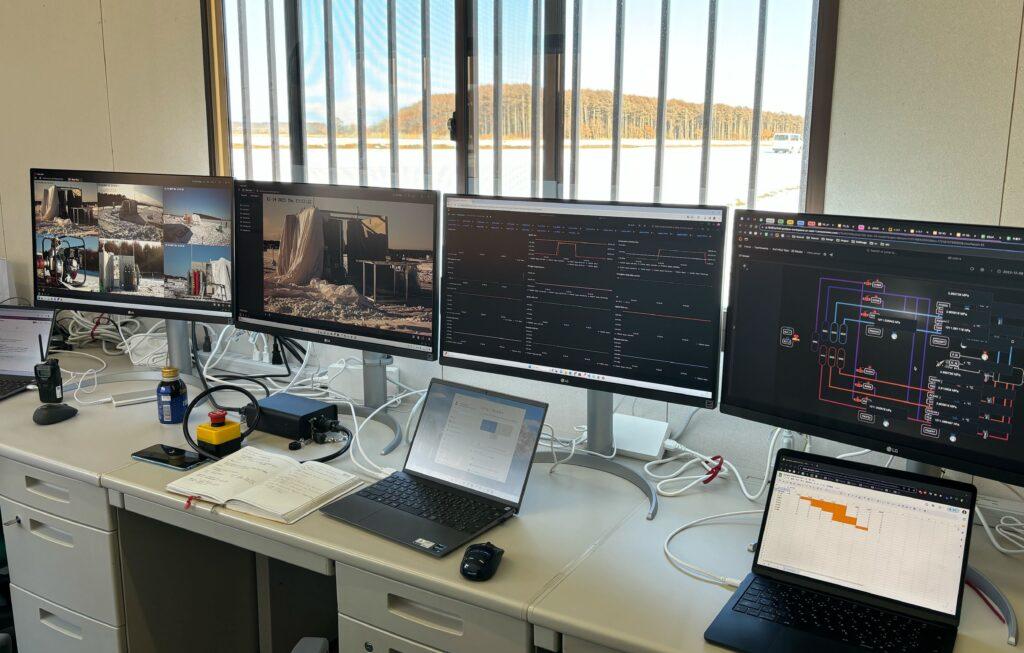

During the Hokkaido burn test conducted last December, we concentrated on the HILS platform, which is further divided into two parts: data collection through IoT and data visualization.

In IoT data collection, there is also the concept of using general-purpose sensors, such as operating one sensor with one microcontroller and doing the rest wirelessly. In the past, there were many wires, and making and wiring them was a very hard job, but with wireless, you can just drop it off and come back.

In the past, we had to think about various things such as making the screen web-based for visualization, but this time we used Grafana and AWS IoT TwinMaker on AWS to create a digital twin environment in a short period of time, which I think is new. I think this is a new way to create a digital twin environment in a short period of time.

By combining these tools, we have been able to reduce human costs and accomplish the process from requirements definition to testing in less than two months, parallel to data collection, which is much shorter than a full-scratch project.

- Are you involved in both the hands-on work, such as installing the sensors in the experimental facility in Taiki Town, and the development part of the development platform?

How has P4SD been effective in combustion testing?

AS A START-UP COMPANY, WE DO WHATEVER WE CAN DO, AND WE HAVE TO SHARE THE WORK AND HELP EACH OTHER. THE BASIC CONCEPT IS BASED ON THE IDEAS OF COO, MR. AKIYUKI NOMURA, BUT THE SPECIFICS HAVE BEEN WORKED OUT BY THE MEMBERS, INCLUDING MYSELF, SINCE THE BEGINNING.

By making it IoT, a key component of the engine, the valve, could be operated wirelessly. I myself am not from the space field. I myself am not from the space field, and this was the first time for me to conduct an engine combustion test, so I was very impressed when other members commented that the test was very good.

- Wouldn't some members who have been in the rocket field for a long time and are familiar with the conventional methods want to use both wired cables and wireless cables and realize their effectiveness before moving on to wireless?

Yes, there was. So we thought about having redundancy. Since there is no room for error in stopping the engine in an emergency, we incorporated both the old wired system and the wireless system.

If we were to do the same thing for all other parts of the rocket, it would take the same amount of time as before, and we would not be able to produce rockets at twice or three times the speed of conventional ones. I think the good thing about this company is that it is not bound by the ties of the past, and I am glad that we were able to take the plunge and challenge the IoT and wireless technology and achieve the results we did.

- HOW WILL P4SD DEVELOP AND BECOME MORE POWERFUL IN THE FUTURE?

In the concept, the design platform part focuses on how engineers can design without spending man-hours in research and development. The point, as has been said, is how to handle data.

BASED ON THE IDEA THAT DESIGNERS ARE PRODUCING DATA SUCH AS DRAWINGS AND CAD DATA, WE ARE TRYING TO FIGURE OUT HOW TO INTEGRATE AND USE IT ALL. IN WORDS, IT IS SOMETHING THAT PROBABLY EVERYONE IN THE MANUFACTURING INDUSTRY IS TRYING TO DO IN THEIR MINDS, BUT IT IS ALSO AN AREA THAT IS DIFFICULT TO BREAK FREE FROM WHEN THERE ARE TIES. IN THAT RESPECT, WE ARE A STARTUP WITH ALMOST NO TIES, SO WE WANT TO TAKE THE PLUNGE AND DO SOMETHING THAT WILL LEAD TO A SHORTER CONSTRUCTION PERIOD.

FOR THE CI/CD PART, WE ARE TRYING TO REALIZE WHAT WE CALL A "PIPELINE" THAT CONNECTS TEST RESULTS TO THE DESIGN PLATFORM, MANAGES DATA FROM TEST RESULTS, AND AUTOMATICALLY STARTS TESTING ON THE COMPUTER WHEN TRIGGERED BY THE DATA. UNTIL NOW, DESIGNERS HAVE HAD TO SEND DRAWING DATA TO THE TESTING DEPARTMENT BY E-MAIL, BUT BY CUTTING OUT SUCH MAN-HOURS, WE HOPE TO ACHIEVE IN A SHORT TIME THE TASKS THAT HUMANS TEND TO MAKE MISTAKES OR FORGET WHEN DOING THEM. I BELIEVE THAT ALL OF THIS WILL CONTRIBUTE TO SHORTENING THE DEVELOPMENT PERIOD.

P4SD STARTED OUT AS AN IDEA ABOUT THE SIZE OF PERAICH THAT WAS THOUGHT UP BY JUST THE TWO OF US, MYSELF AND MR. NOMURA. AFTER A LOT OF HARD WORK, IT FINALLY TOOK SHAPE IN THE FORM OF THIS COMBUSTION TEST. ALTHOUGH THE SYSTEM WAS STILL IN ITS INFANCY, WE HAD BUILT IT UP FROM NOTHING IN ORDER TO CONTRIBUTE TO CUTTING THE ROCKET DEVELOPMENT PERIOD IN HALF OR EVEN IN ONE-THIRD. FOR MY PART, THE NUMBER OF MEMBERS HAS INCREASED, WE HAVE STARTED WORKING WITH PARTNER COMPANIES, AND I HAVE JUST GOTTEN A GOOD FEELING THAT "WITH THIS, WE CAN CERTAINLY CREATE A DEVELOPMENT PLATFORM THAT NO ONE ELSE IN THE WORLD HAS DONE BEFORE. I THINK I WILL BE ABLE TO DO MY BEST TO ACHIEVE THIS DREAM.

2. COMMUNICATION SKILLS AMONG MEMBERS FROM DIFFERENT BACKGROUNDS IN THE IT ENGINEERING STYLE

- What is your background and how did you come to rocket development?

In fact, I have been a dabbler in automobiles, which I love, and a scuba diving instructor for quite some time since I graduated from college.

As expected, my parents were angry with me, and I decided to pursue my favorite career in automobiles, so I spent about four years in Honda's research laboratories, and from there about 15 years at Toyota Systems.

I WAS WORKING ON IT SYSTEMS SUCH AS CAD AND "BILL OF MATERIALS (BOM)" WITHIN AN AUTOMOBILE MANUFACTURER. THERE IS A DEVICE CALLED AN AUTOMOBILE TROUBLE DIAGNOSTIC MACHINE, WHICH INDICATES THE LOCATION OF A MALFUNCTION WHEN A PC IS CONNECTED TO THE CAR, AND I HAVE NEARLY FIVE YEARS OF EXPERIENCE IN SOFTWARE DEVELOPMENT FOR THIS DEVICE.

In my private life, my children were already quite grown up, and when I thought I had reached the end of my child-rearing years, I was asked if I would like to work with them. At first, I thought the name "Future Space Transportation Systems" sounded a bit suspicious, but after listening to what they had to say, it sounded interesting and would give me a chance to get in touch with space. So after much thought, I took the plunge.

- Coming from a field outside of space, do you have any tips on how to communicate well and what you keep in mind in terms of how to facilitate discussions and communication within the team?

WHEN YOU'VE BEEN IN THE IT PROFESSION FOR A LONG TIME, YOU ACTUALLY OFTEN GET SMOKED BY ENGINEERS AND DESIGNERS. I SOMETIMES FEEL THAT THEY SEE ME AS OBLIQUE AND JARGON-LADEN.

ON THE OTHER HAND, IF THE USERS DON'T SPEAK THEIR MIND, YOU END UP WITH A SYSTEM THAT IS DIFFICULT TO USE AND NOT USED. I WOULD RATHER BE A BIT OF A CLUNKER AND REMAIN AS EASY A CHARACTER TO TALK TO AS POSSIBLE.

- I understand that the environment is very fast-paced, but is there anything you keep in mind when switching on and off?

Actually, my home is in Aichi Prefecture, and for a while after I changed jobs, I commuted from my parents' home in Saitama Prefecture. Therefore, I hardly saw my family at all.

This year, I have become accustomed to my job and am working remotely from Aichi Prefecture. I can stay home and talk with my family after work. I realize that family is important after all. Now I am intentionally separating on and off, and I am trying to make a break from this because it is family time from here on.

- What kind of person would you like to see as a future member of the team for Space Transportation Systems?

First of all, we are chronically short of staff, so we will not refuse anything that comes our way.

However, I have my own area of expertise, and there are times when I take on jobs that require more than just software, such as building IoT devices. I am not a professional in the networking field either, but I have to work with someone else to set up the network, so I might take on a job for them. So, while I have a specialty, it would be nice if I could be actively involved in peripheral areas as well.

I also have to think about how to make things happen, and I hope that my colleagues will be able to work with that kind of mindset, making their own decisions and finishing the job.