INNOVATIVE SPACE CARRIER INC.(CHUO-KU, TOKYO; CEO; KOJIRO HATADA, HEREAFTER REFERRED TO AS "ISC") IS "A WORLD WHERE PEOPLE AND CARGO ARE DELIVERED EVERY DAY. WE ARE A START-UP COMPANY THAT AIMS TO REALIZE A TRANSPORTATION SYSTEM THAT MAKES SPACE POSSIBLE, WITH THE VISION OF "MAKING SUCH THINGS POSSIBLE IN SPACE. ( REUSABLE) IS A START-UP COMPANY THAT AIMS TO REALIZE A TRANSPORTATION SYSTEM THAT MAKES SPACE POSSIBLE.

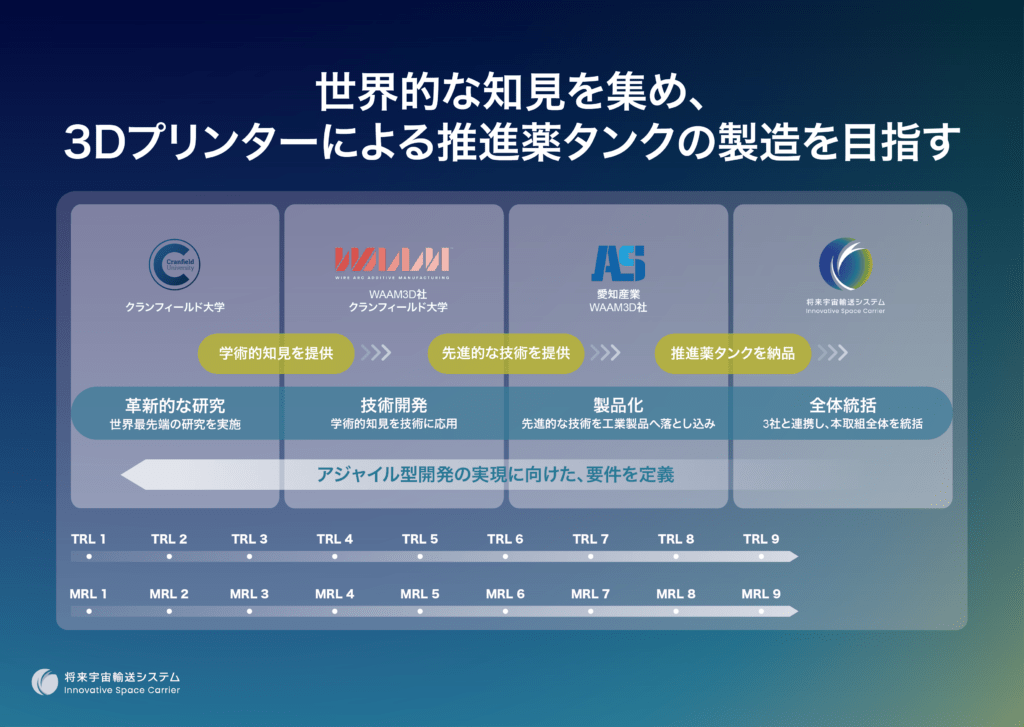

ON JULY 19 (FRI.), WE ENTERED INTO A BUSINESS ALLIANCE WITH WAAM3D, A UK-BASED 3D PRINTER MANUFACTURER, CRANFIELD UNIVERSITY, WHICH HAS WORLD-CLASS KNOWLEDGE OF WAAM TECHNOLOGY (*1), AND AICHI SANGYO, A PIONEER IN METAL AM IN JAPAN, TO MANUFACTURE A PROPELLANT TANK USING A 3D PRINTER. LTD. WHICH HAS BEEN WORKING ON METAL AM FOR SOME TIME IN JAPAN, TO MANUFACTURE PROPELLANT TANKS USING 3D PRINTERS.

THIS BUSINESS ALLIANCE AMONG THE FOUR COMPANIES WILL INVOLVE THE PRODUCTION OF PROPELLANT TANKS USING 3D PRINTERS.

Furthermore, we will promote the sharing of each company's knowledge and examine other components and structures to achieve an agile type of development.

※1 WAAM技術とは、Wire-Arc Additive Manufacturingの略称。金属同士をつなげるアーク溶接の手法を応用し、溶接中に凝固した金属を積層していく手法。アメリカ国防総省が潜水艦の部品の造形のために導入するなど、大型構造物の造形が可能。

3D PRINTER ENABLES AGILE DEVELOPMENT

We are a venture company founded in May 2022 with the challenging goal of developing a reusable space transportation vehicle in the next five years or so. To achieve this goal, a dramatic improvement in development efficiency is essential.

To this end, we aim to realize agile development rather than the traditional waterfall approach. In December last year, we conducted our first test and successfully conducted Japan's first "tripropellant method" burn test, and also confirmed the effectiveness of our proprietary research and development platform, "P4SD" (Platform for Space Development).

3D PRINTERS ARE ESSENTIAL TO THE REALIZATION OF AGILE-TYPE DEVELOPMENT.

THE SHORTENED MANUFACTURING TIME ALLOWS FOR RAPID REPETITION OF MANUFACTURING, TESTING, AND MODIFICATION, WHICH IS EXPECTED TO INCREASE DEVELOPMENT SPEED. IN ADDITION, SINCE 3D PRINTERS ENABLE INTEGRATED FORMING, THERE ARE SIGNIFICANT ADVANTAGES IN TERMS OF MANAGEMENT AND ASSEMBLY, AS OPPOSED TO THE CONVENTIONAL PRACTICE OF FORMING EACH PART AND ASSEMBLING IT SEPARATELY. IN ADDITION, THE HIGH DEGREE OF FREEDOM OF MODELING ALLOWS FOR OPTIMAL SHAPES AND IMPROVED FUNCTIONALITY, AS WELL AS WEIGHT REDUCTION.

THIS BUSINESS ALLIANCE AMONG THE FOUR COMPANIES WILL INVOLVE THE PRODUCTION OF PROPELLANT TANKS USING 3D PRINTERS.

Furthermore, we will promote the sharing of each company's knowledge and examine other components and structures to achieve an agile type of development.

GATHERING GLOBAL KNOWLEDGE TO MANUFACTURE PROPELLANT TANKS WITH 3D PRINTERS

WE HAVE RECENTLY ENTERED INTO A BUSINESS ALLIANCE WITH WAAM3D, A UK-BASED 3D PRINTER MANUFACTURER, CRANFIELD UNIVERSITY, WHICH HAS WORLD-CLASS KNOWLEDGE OF WAAM TECHNOLOGY, AND AICHI SANGYO CORPORATION, WHICH WAS ONE OF THE FIRST COMPANIES IN JAPAN TO ENGAGE IN THE METAL AM TECHNOLOGY, TO BEGIN MANUFACTURING PROPELLANT TANKS USING 3D PRINTERS. THE COMPANY HAS DECIDED TO BEGIN MANUFACTURING PROPELLANT TANKS USING A 3D PRINTER.

BY COLLABORATING WITH OTHER COMPANIES WITH WORLD-CLASS KNOWLEDGE, WE WILL PROMOTE THE DEMONSTRATION OF THE USE OF 3D PRINTERS IN THE SPACE INDUSTRY.

WAAM3D, Inc. is a venture company spun off from Cranfield University. The company provides a full range of services, from in-house development of WAAM equipment to the creation of materials for manufacturing. The company's technology is used in a wide range of industries, including the space industry, the oil and gas industry, and the mining industry.

The company's WAAM equipment is based on conventional arc welding machines and articulated robots, so theoretically there is no limit to the size of the workpieces to be formed. Therefore, the generation of molding paths, fine-tuning of molding conditions, and control of heat input are major issues in WAAM technology, but the company has succeeded in developing software and various sensors to assist in these tasks, enabling visualization and feedback control of the molding technology. Under this business alliance, MHI will purchase WAAM3D's 3D printers and manufacture propellant tanks.

CRANFIELD UNIVERSITY IS A WORLD-CLASS KNOWLEDGE CENTER FOR WAAM TECHNOLOGY AND HAS OVER 15 YEARS OF EXPERIENCE IN METAL AM RESEARCH. THE WELDING AND ADDITIVE MANUFACTURING CENTER AT CRANFIELD UNIVERSITY IS ONE OF THE LARGEST METAL ADDITIVE MANUFACTURING FACILITIES IN THE WORLD, EQUIPPED WITH NOT ONLY VARIOUS ARC WELDING MACHINES, BUT ALSO MULTIPLE LASER PROCESSING SYSTEMS, AND FACILITIES FOR STRESS CONTROL AND ANALYSIS DURING AND AFTER FABRICATION, WHERE RESEARCH ON MATERIAL DEVELOPMENT, COLD WORKING, ADVANCED PROCESSES, AND PARTIAL MANUFACTURING IS CONDUCTED. AS PART OF ITS RESEARCH ACTIVITIES, THE BUSINESS ALLIANCE WILL UTILIZE THE UNIVERSITY'S EXPERTISE IN THE MANUFACTURE OF PROPELLANT TANKS.

IN THE 80 YEARS SINCE ITS ESTABLISHMENT, AICHI SANGYO HAS INTRODUCED THE WORLD'S MOST ADVANCED WELDING, MELTING, AND FUSING TECHNOLOGIES TO THE JAPANESE MARKET AS A TECHNOLOGY TRADING COMPANY. AS A TECHNOLOGY PROPOSAL-ORIENTED COMPANY, WE NOT ONLY INTRODUCE OVERSEAS TECHNOLOGIES, BUT ALSO HAVE A WEALTH OF EXPERIENCE IN THIS FIELD. WE WERE ONE OF THE FIRST COMPANIES IN JAPAN TO WORK ON METAL ADDITIVE MANUFACTURING TECHNOLOGY, AND WE NOT ONLY SELL EQUIPMENT, BUT WE ALSO USE IT DAILY AS A JOB STORE, GAINING EXPERIENCE IN ITS USE. WE PROVIDE TOTAL AM SOLUTIONS THAT INTEGRATE THE THREE ELEMENTS OF METAL AM: (1) SYSTEMS (MANUFACTURING EQUIPMENT), (2) MATERIALS, AND (3) DESIGN (MANUFACTURING TECHNOLOGY). IN THIS BUSINESS ALLIANCE, WE WILL UTILIZE WAAM3D'S 3D PRINTER, WHICH WE PURCHASED, TO DEVELOP TECHNOLOGY FOR THE MANUFACTURE OF PROPELLANT TANKS.

A TOTAL OF FOUR COMPANIES, THE ABOVE THREE AND OUR COMPANY, WILL MANUFACTURE PROPELLANT TANKS USING 3D PRINTERS.

Furthermore, based on this business alliance, we will promote the sharing of each company's knowledge, and will also examine other components and structures to realize agile-type development.

■Future Space Carrier Inc. company profile

Corporate name Innovative Space Carrier Inc.

English name Innovative Space Carrier Inc.

Representative CEOKojiro Hatada

Head office address 1-4-1 Nihonbashi, Chuo-ku, Tokyo

Date of establishment May 2, 2022

Total funding 860,000,000 yen

Business description Planning for the commercialization of innovative space transportation systems Study

URL https://innovative-space-carrier.co.jp/

■Aichi Sangyo Corporation Company Profile

Corporate Name: Aichi Sangyo Co.,Ltd.

English Name: Aichi Sangyo Co.,Ltd.

Representative CEOHiroki Inoue

Head Office Address: 2-6-8 Higashioi, Shinagawa-ku, Tokyo

Business Description Development, design, manufacture and sales of in-house products by importing the most advanced technologies in the world, focusing on welding technology, metallurgy technology and machine tool-related products

URL https://www.aichi-sangyo.co.jp

■ WAAM3D Company Profile

Representative CEO Filomeno Martina

Head Office Address 5 Thornton Chase, Milton Keynes, MK14 6FD United Kingdom

Date Established 2018

Business Development of state-of-the-art WAAM additive manufacturing technologies

URL https://www.waam3d.com/

■ Cranfield University Overview

Name of Institution Cranfield University

Location College Road, Cranfield, Bedfordshire, MK43 0AL, United Kingdom

Principal Professor Professor Stewart Williams

Research Welding Science and Engineering

URL https://www.cranfield.ac.uk/

Innovative Space Carrier Inc. CEOKojiro Hatada, President Comment

Although we are a venture company founded in May 2022, we are currently working with over 40 companies, organizations, and educational institutions in Japan.

In April this year, we formed a business alliance with Ursa Major Technologies, a U.S. rocket engine developer, and established a local subsidiary. Following this, we have recently formed business alliances with companies that have global knowledge of 3D printers.

Our goal is to be "Japanese spirit with Western learning. We will humbly learn from our partners, both in Japan and abroad, who possess cutting-edge knowledge, and reflect this knowledge to Japan's strengths. We will also grow Japan's space industry by dramatically increasing the speed of development and establishing space transportation technology that can compete globally!

Dr Filomeno Martina, CEO of WAAM3D comments

With partners of such calibre, we look forward to pushing the boundaries of size, integrity , and value creation. WAAM3D continues to be the first choice when performance matters."

(Contact person's transliteration)

We are very excited to be working on such an ambitious project. We also look forward to working with our talented partners to push the boundaries of scale, precision, and new value creation in manufacturing with 3D printers.

WAAM3D CONTINUES TO BE THE FIRST CHOICE FOR PERFORMANCE-DRIVEN MANUFACTURING.

*English version below

Innovative Space Carrier Inc. Partners with Global Leaders to Revolutionize Propellant Tank Manufacturing with Metal Additive Manufacturing (AM) Propellant Tank Manufacturing with Metal Additive Manufacturing (AM) Technology

Tokyo, Japan - [19/7/2024] - Innovative Space Carrier Inc. (ISC), a visionary space startup aiming to make space accessible to everyone, announces a groundbreaking partnership to manufacture propellant tanks using metal Additive Manufacturing (AM) technology for the first time in Japan. space startup aiming to make space accessible to everyone, announces a groundbreaking partnership to manufacture propellant tanks using metal Additive Manufacturing (AM) technology for the first time in Japan.

Collaboration for Agile Development

ISC has joined forces with WAAM3D, a leading WAAM hardware, software and materials organisation in the UK, Cranfield University, a world-renowned This strategic collaboration leverages the expertise of each partner to achieve agile development in propellant development. This strategic collaboration leverages the expertise of each partner to achieve agile development in propellant tank production.

Revolutionizing Development Speed with AM

"Founded in 2022, our goal is to develop a reusable space vehicle within the next five years," says Kojiro Hatada, CEO of ISC. "To achieve this goal, a dramatic improvement in development efficiency is essential and have adopted agile development over traditional models and, in December, successfully conducted Japan's first "reusable space vehicle" development. "To achieve this goal, a dramatic improvement in development efficiency is essential and has adopted agile development over traditional models and, in December, successfully conducted Japan's first "tri-propellant' combustion test, verifying the effectiveness of our proprietary We position AM technology as crucial for achieving a dramatic improvement in development efficiency is essential and have adopted agile development over traditional models and, in December, successfully conducted Japan's first "tri-propellant' combustion test, verifying the effectiveness of our proprietary "P4SD" (Platform for Space Development). We position AM technology as crucial for achieving this ambitious goal by enabling rapid prototyping, testing, and design optimization. partnership signifies a significant leap forward in our development process.

Global Expertise for Metal AM

WAAM3D brings its industry-leading WAAM technology and ecosystem to the table. Cranfield University contributes its extensive research and knowledge in metal AM, while Aichi Sangyo offers its experience in implementing AM solutions and deep understanding of the Japanese market.

Unlocking the Potential of AM in the Space Industry

"By combining our expertise, we aim to showcase the transformative potential of metal AM in the space industry," says Dr. Filomeno Martina, CEO of WAAM3D. "This collaboration will not only revolutionize propellant tank manufacturing but also pave the way for future applications of AM in spacecraft development."

About Innovative Space Carrier Inc.

Innovative Space Carrier Inc. (ISC) is a venture company founded in May 2022 with the ambitious goal of developing a reusable space vehicle. The company leverages agile development methodologies and cutting-edge technologies to accelerate its mission of making space accessible to everyone.

About WAAM3D

WAAM3D is the only provider of a total, turnkey solution delivered via a WAAM ecosystem that is based on in-house developed products, services, and materials. By pushing the boundaries of WAAM capabilities, WAAM3D is helping those in aerospace, oil and gas, mining, and other industrial applications to have increased design freedom, reduce costs and By pushing the boundaries of WAAM capabilities, WAAM3D is helping those in aerospace, oil and gas, mining, and other industrial applications to have increased design freedom, reduce costs and shorten lead times of a range of medium-to-large sized components. WAAM3D has been focusing on enabling the manufacture of mission-critical components since the very beginning of this journey.

WAAM3D's equipment is based on articulated robots, so theoretically, there is no limit to the size of the workpiece that can be formed. The generation of deposition paths, the fine-tuning of WAAM parameters, and the management of residual stress and distortion are all significant issues in WAAM processing. However, the company has succeeded in developing software and various sensors to address these challenges in a scientifically robust way. Under this alliance, ISC chose WAAM3D's system to manufacture propellant tanks.

About Cranfield University

Cranfield University is a research institution with world-class knowledge of WAAM technology and has almost 20 years of experience in metal AM research. The university's Welding and Additive Manufacturing Center is one of the world's largest metal additive manufacturing facilities, equipped not only with various arc-based machines but also multiple laser processing systems and facilities for stress control and analysis during and after fabrication, where research is conducted on material development, cold working, advanced processes and hybrid manufacturing. Under this business alliance, Aichi Sangyo will utilise the university's expertise in the manufacture of propellant Under this business alliance, Aichi Sangyo will utilize the university's expertise in the manufacture of propellant tanks as part of its research activities.

About Aichi Sangyo Co.

Aichi Sangyo has introduced the world's most advanced welding, melting, and melting technologies to the Japanese market as a technology As a technology proposal-oriented company, Aichi Sangyo introduces overseas technologies and has a wealth of experience in this field. They are one of the first companies in Japan to work on metal additive manufacturing technology, and we not only sell equipment but also use the equipment daily. We provide total AM solutions that integrate the three elements of metal AM: (1) systems (manufacturing equipment), (2) materials, and (3) design (manufacturing technology). In this business alliance, we will utilize WAAM3D's AM system, which we purchased, to develop technology for manufacturing propellant tanks.

■We are actively recruiting personnel!

We want to go to space from Japan.

We take on challenges.

Aerospace technology x Knowledge of different industries x Backcast thinking

Create new industries with an eye on the future.

Let's do a job worth challenging with our life.

Click here for the employment page:

https://www.wantedly.com/companies/company_9146989

For business partnerships and other inquiries, click here

https://innovative-space-carrier.co.jp/contact/

■We are accepting "advanced applications" for space travel

Please follow this link to register.

https://forms.gle/TDc8HpdcR2zCU41t9