Innovative Space Carrier Inc.(Chuo-ku, Tokyo; CEOKojiro Hatada), a start-up company that aims to realize a transportation system that makes space reusablepossible, has succeeded in Japan's first "tripropellant" combustion test using three types of propellants: hydrogen, methane, and oxygen.

In addition, we have confirmed the effectiveness of our proprietary research and development platform "P4SD" (Platform for Space Development).

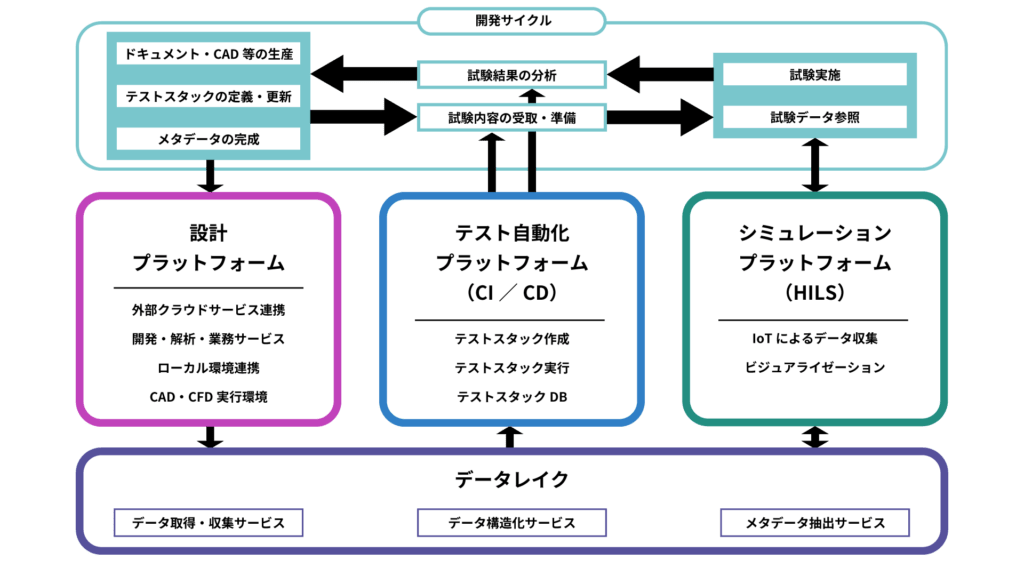

P4SD (Platform for Space Development) is our original research and development platform. All processes related to development, including research, design, and experiments, are converted into data and consolidated in the cloud. It enables seamless and open development, and can dramatically improve development efficiency. (See below for details).

summary

- Date: Tuesday, December 19 - Wednesday, December 20, 2023

- LOCATION: HOKKAIDO SPACE PORT (HOSPO) RUNWAY

results

- Success of Japan's first "tripropellant combustion test" using three types of propellants: hydrogen, methane, and oxygen.

- CONFIRMATION OF THE EFFECTIVENESS OF P4SD, A RESEARCH AND DEVELOPMENT PLATFORM FOR AGILE DEVELOPMENT

background

WE BELIEVE IN "A WORLD WHERE PEOPLE AND CARGO ARE DELIVERED EVERY DAY. OUR VISION IS TO ACHIEVE HIGH-FREQUENCY SPACE TRANSPORTATION IN THE 2040S USING FULLY REUSABLE SINGLE-STAGE SPACE VEHICLES (SSTOS). OUR VISION IS TO DEVELOP A REUSABLE SPACE TRANSPORTATION VEHICLE IN THE NEXT FIVE YEARS, WITH THE ULTIMATE GOAL OF CONDUCTING HIGH-FREQUENCY SPACE TRANSPORTATION USING A FULLY REUSABLE SINGLE-STAGE SPACE REUSABLEVEHICLE (SSTO) IN THE 2040S.

Succeeded in Japan's first "tripropellant method combustion test

IN ORDER TO REALIZE A FULLY REUSABLE SINGLE-STAGE SPACECRAFT REUSABLE(SSTO), IT IS ESSENTIAL TO REDUCE THE WEIGHT OF THE AIRFRAME. WE ARE CHALLENGING THE APPLICATION OF THE TRIPROPELLANT METHOD AS A MEANS OF REDUCING THE WEIGHT OF THE AIRFRAME. THE USE OF HYDROGEN FUEL, WHICH HAS LOW DENSITY AND HIGH SPECIFIC IMPULSE, IS CONCENTRATED IN THE OUTER ATMOSPHERE, AND METHANE FUEL IS USED TO COVER THE THRUST IN THE ATMOSPHERE.

In this test, we worked on a "tripropellant combustion test" using three types of propellants, hydrogen, methane, and oxygen, and succeeded in obtaining the expected test results.

IN ADDITION, THIS COMBUSTION TEST WAS CONDUCTED TO VERIFY THE EFFECTIVENESS OF OUR PROPRIETARY RESEARCH AND DEVELOPMENT PLATFORM, P4SD. Agile development is achieved. To achieve the challenging goal of "developing a reusable space transportation vehicle in the next five years," it is essential to dramatically improve development efficiency. In the past, development was generally conducted in a waterfall style, which resulted in a prolonged development period due to the stove-piping of each process and lack of flexibility in changing specifications. Therefore, we use our own research and development platform, "P4SD" (Platform for Space Development), to achieve agile development. P4SD" IS A RESEARCH AND DEVELOPMENT PLATFORM THAT CONVERTS ALL DEVELOPMENT-RELATED PROCESSES INTO DATA AND CONSOLIDATES THEM ON THE CLOUD. IT CONVERTS RESEARCH AND DESIGN, AS WELL AS TEST RESULTS, INTO DATA AND CONSOLIDATES THEM. ALL ASPECTS OF DEVELOPMENT, INCLUDING SUBSEQUENT ANALYSIS AND IMPROVEMENT, CAN BE CENTRALLY MANAGED. P4SD was built using AWS (Amazon Web Services). Agile development was used to achieve low-cost and quick construction. P4SD" MAKES IT POSSIBLE FOR ALL MEMBERS INVOLVED IN DEVELOPMENT TO OBTAIN THE SAME INFORMATION ANYTIME, ANYWHERE, AND ENABLES AGILE DEVELOPMENT. Confirmation of effectiveness by combustion test THE EFFECTIVENESS OF THE P4SD HAS NOW BEEN CONFIRMED IN A COMBUSTION TEST CONDUCTED FROM TUESDAY, DECEMBER 19 TO WEDNESDAY, DECEMBER 20, 2023. Phase 1: Research and design First, information is consolidated during the research and design phase, which is the preliminary stage of combustion testing. THE USE OF 3D PRINTERS IN THE DESIGN OF SOME OF THE TEST AIRCRAFTS THAT FOLLOWED REDUCED THE MANUFACTURING TIME AND COST, AND MADE IT POSSIBLE TO CONDUCT THE TESTS WITHIN A SHORT PERIOD OF ONLY THREE MONTHS FROM THE START OF THE STUDY. THE TEST WAS CONDUCTED WITHIN A SHORT PERIOD OF ONLY THREE MONTHS FROM THE START OF THE STUDY. Phase 2: Measurement of test results Then, we produced a proprietary control sensor. Each control sensor monitors independently and immediately transmits data to the cloud wirelessly. This "one-microcomputer, one-sensor" approach eliminates the need for wired cables for data transmission in the vicinity of the test rig, contributing to more efficient construction of the test environment. During the test, control sensors were installed around the test fuselage. Various data such as temperature and pressure were acquired. Phase 3: Consolidation of test results Various data acquired by the sensors were transmitted in real time, and were checked and analyzed collectively on the cloud server. IN THIS TEST, THE EFFECTIVENESS OF "P4SD" WAS CONFIRMED BY SUCCESSFULLY CONVERTING ALL PROCESSES IN DEVELOPMENT, INCLUDING RESEARCH, DESIGN, EXPERIMENTATION, MEASUREMENT, ANALYSIS, AND IMPROVEMENT, INTO DATA AND CONSOLIDATING THEM ON THE CLOUD. IN THE FUTURE, BASED ON THE IDEA OF "ONE MICROCOMPUTER, ONE SENSOR," WE WILL FURTHER IMPROVE "P4SD" WITH AWS AS THE AXIS, AND ACCELERATE RESEARCH AND DEVELOPMENT. WE WILL CONTINUE TO CONDUCT HIGH-FREQUENCY EXPERIMENTS USING OUR PROPRIETARY RESEARCH AND DEVELOPMENT PLATFORM "P4SD," AND BY REPEATING VARIOUS TESTS, INCLUDING THE TRIPROPELLANT BURN TEST, WE WILL MAKE THE "P4SD" MORE USER-FRIENDLY AND REALIZE A REUSABLE SPACECRAFT AS SOON AS POSSIBLE. WE WILL ALSO REALIZE A REUSABLE SPACECRAFT AS SOON AS POSSIBLE. Within a short period of about three months from the planning of the combustion test, preparations proceeded smoothly and the test results were achieved as originally planned. We believe that the success of the test was due to the bold challenge taken on by our mid-career and young engineers, including some with no experience in the space industry, while receiving accurate advice from veteran personnel with a wealth of experience. ALTHOUGH OUR COMPANY IS A START-UP THAT HAS ONLY BEEN IN BUSINESS FOR ABOUT A YEAR AND A HALF, WE FEEL VERY CONFIDENT THAT WE HAVE ASSEMBLED A GROUP OF TALENTED PEOPLE WHO CAN CARRY OUT DEVELOPMENT IN A PRECISE AND SPEEDY MANNER. THROUGH THIS DEVELOPMENT, WE HAVE NOT ONLY LEARNED TEST OPERATION KNOW-HOW, BUT HAVE ALSO BEEN ABLE TO LAUNCH "P4SD," A PLATFORM FOR AGILE RESEARCH AND DEVELOPMENT. WITH THE COOPERATION OF OUR MANY PARTNERS, WE WILL CONTINUE TO WORK TOWARD THE REALIZATION OF THE SPACE TRANSPORTATION SYSTEM OF THE FUTURE AT AN UNPRECEDENTED PACE. We want to work together with individuals who want to work together with us! Whether you are an individual who wants to work with us, or a corporation who wants to collaborate with us as a business partner, let's challenge this project together to make this dream come true! and corporations who want to collaborate with us as business partners, let's challenge this project together to make a dream-like future a reality. We have a job in front of us that we should bet our lives on. We look forward to hearing from you. Click here for the recruitment page: https://innovative-space-carrier.co.jp/careers/ Click here to contact us for business collaboration and other inquiries:

CONFIRMATION OF THE EFFECTIVENESS OF P4SD, A RESEARCH AND DEVELOPMENT PLATFORM THAT DRAMATICALLY IMPROVES DEVELOPMENT EFFICIENCY

KOJIRO HATATA CEOPRESIDENT AND CEO COMMENTS